Redefine productivity at every level

If you are seriously looking for ways to raise your bottom line, shouldn’t you be looking at your entire process? Measures to increase productivity must work in concert with processes at every level, including material handling, to efficiently manage increased production volume. Fusion System Group specializes in material handling machines and custom equipment for every level of your operation.

Speed and precision at competitive prices

Concerned about committing to the financial investment in new material handling machines? FSG develops material handling systems that are more affordable than you may have ever thought possible. That is because we develop custom material handling solutions that deliver exactly what you need and nothing that you don’t. Material handling machines from FSG actually save your organization money while creating a level of production efficiency that meets and exceeds your goals.

Material handling machines that provide turnkey solutions

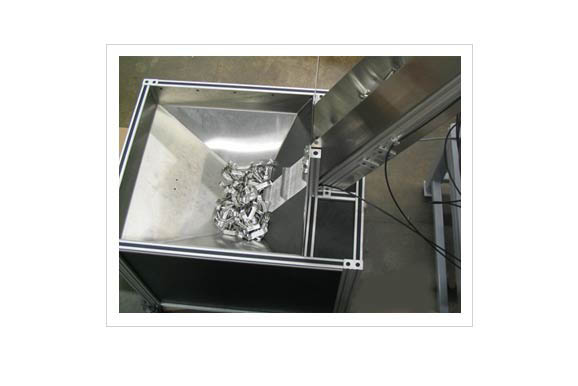

Your material handling equipment upgrade should make your life easier, not more complicated. That is why FSG offers you turnkey material handling machines that are designed to integrate seamlessly into your operation. Pre-engineered systems such as those in the gallery below provide payoff performance at lower costs. We build material handling machines at a wide spectrum of customization, for businesses of any size.

Our engineering team takes our responsibility very seriously. You can count on us to design to exact specifications, and to manage your project from process analysis through continued use. FSG has built dependable material handling machines for over 50 years.

Call 1-800-626-9501 to speak with an FSG material handling engineer. Ours is a customer service guarantee you can rely on. We look forward to maximizing your production.